How Thermal Management Works in Hydrogen Fuel Cell Electric Vehicles

- Share

- Issue Time

- Sep 15,2025

Summary

Effective thermal management is critical for optimizing the performance, efficiency, and lifespan of FCEVs

Understanding the Basics of Thermal Management in FCEVs

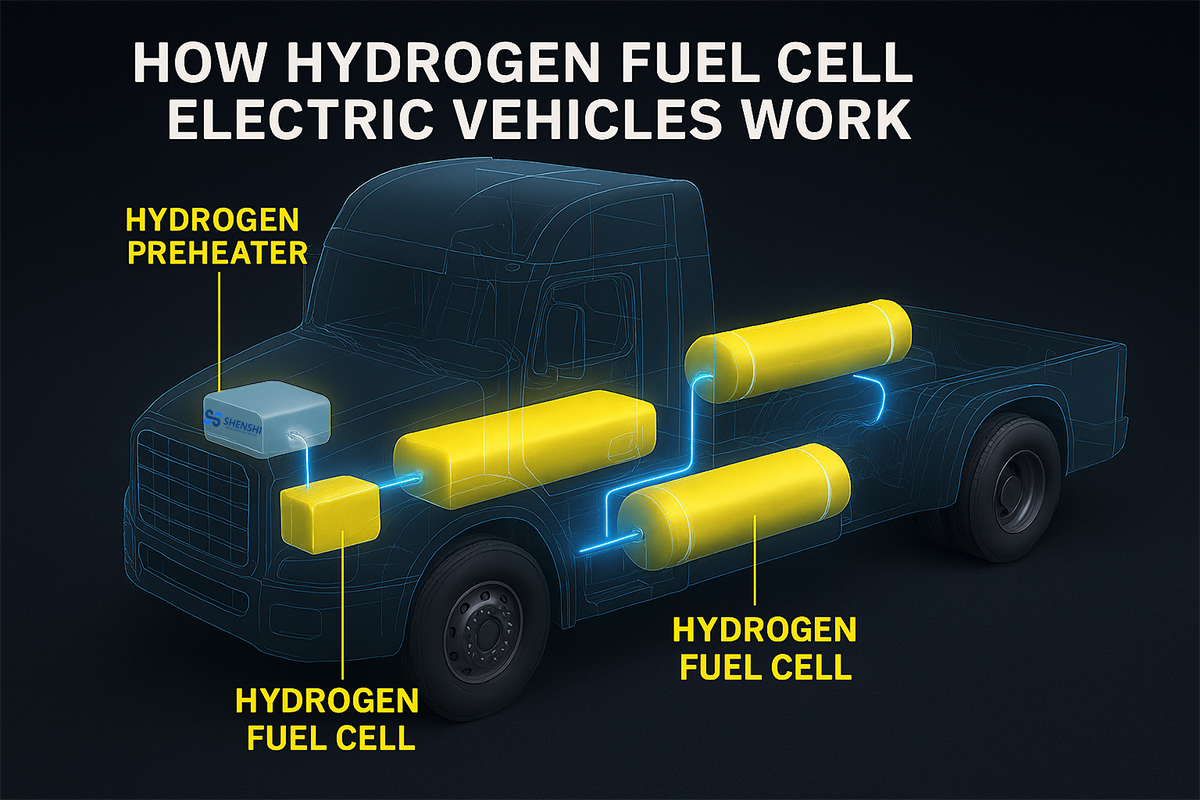

Hydrogen fuel cell electric vehicles (FCEVs) generate electricity through a chemical reaction between hydrogen and oxygen, producing water and heat as byproducts. The thermal management system (TMS) regulates this heat to maintain optimal operating temperatures (typically 60-80°C for proton exchange membrane fuel cells). Our experience with 70kW, 110kW, and 120kW heat exchangers—designed for efficient hydrogen preheating and cooling—highlights the importance of precise temperature control to prevent efficiency losses and component degradation.

- Heat Generation: The fuel cell stack produces significant heat during power generation, necessitating robust cooling.

- Operational Goal: Maintain a stable thermal environment to enhance electrochemical reactions and durability.

- Industry Insight: Research from leading institutions like NREL emphasizes TMS as a cornerstone of FCEV reliability.

Key Components of the Thermal Management System

The TMS integrates several high-quality components to manage heat effectively, as seen in the diagram of the SHENSHI onboard hydrogen supply system.

Components

- Heat Exchangers: Microchannel designs (70kW, 110kW, 120kW variants) facilitate efficient heat transfer.

- Coolant Loops: Circulate specialized fluid to absorb and dissipate heat.

- Pumps and Valves: Regulate coolant flow and pressure for dynamic thermal control.

- Sensors and Controls: Monitor temperatures and adjust systems in real-time.

This integrated approach, validated by our work with fuel cell trucks, ensures optimal performance across diverse operating conditions.

How Heat Transfer Works in FCEVs

Heat transfer in FCEVs follows a multi-step process to safeguard the system:

- Heat Absorption: Coolant absorbs heat from the fuel cell stack, preventing overheating.

- Heat Exchange: The absorbed heat is transferred to the heat exchanger, dissipated to the outside air or a secondary loop.

- Temperature Regulation: Advanced controls adjust coolant flow to maintain ideal conditions.

- Efficiency Optimization: Effective heat management reduces energy waste, aligning with sustainability goals.

Our hands-on experience with heavy-duty hydrogen trucks underscores the precision required in this process.

Benefits of Efficient Thermal Management

Proper thermal management offers tangible benefits, supported by industry data and our practical implementations:

- Enhanced Efficiency: Stable temperatures improve fuel cell output by up to 10-15%, according to SAE studies.

- Extended Lifespan: Controlled heat reduces membrane degradation, extending stack life by years.

- Safety Assurance: Prevents thermal runaway, critical in high-power FCEVs like those using 120kW systems.

- Environmental Impact: Optimized systems reduce energy consumption, supporting cleaner hydrogen vehicle adoption.

Challenges and Solutions

Despite advancements, thermal management faces challenges:

- High Heat Loads: Addressed by our 110kW and 120kW exchangers with enhanced cooling capacity.

- Compact Design Needs: Met with our compact microchannel technology.

- Cold Start Issues: Innovative preheating strategies in our 70kW units ensure reliable startups.

Our engineering team leverages cutting-edge research and testing to overcome these hurdles.

Future Trends and Innovations

The future of FCEV thermal management is promising, with trends we actively influence:

- Advanced Materials: Lightweight, heat-resistant alloys for heat exchangers.

- AI-Driven Controls: Smart systems for real-time thermal optimization.

- Integration with Renewables: Aligning TMS with hydrogen production from green sources.

Stay ahead with our insights by subscribing to our newsletter for the latest updates.

Conclusion

Understanding thermal management in hydrogen fuel cell electric vehicles is key to unlocking their full potential. At shenshiec.com, our expertise in designing heat exchangers—like those powering the HZSS onboard systems—positions us as a leader in this field. Whether you’re a fleet operator, engineer, or enthusiast, we’re here to support your needs with proven solutions.

Explore our range of thermal management products or contact our experts for a customized consultation. Download our free guide on FCEV thermal optimization today!