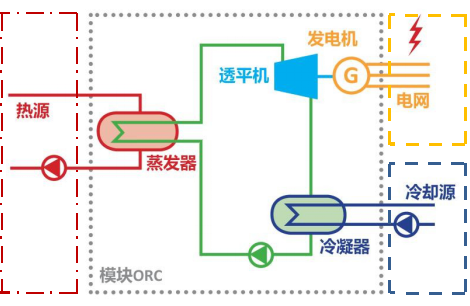

In order to improve the efficiency of the organic Rankine cycle system, it is necessary to optimize the design of the system, including the determination of cycle thermodynamic parameters, the selection of working fluids, and the design of heat exchangers.

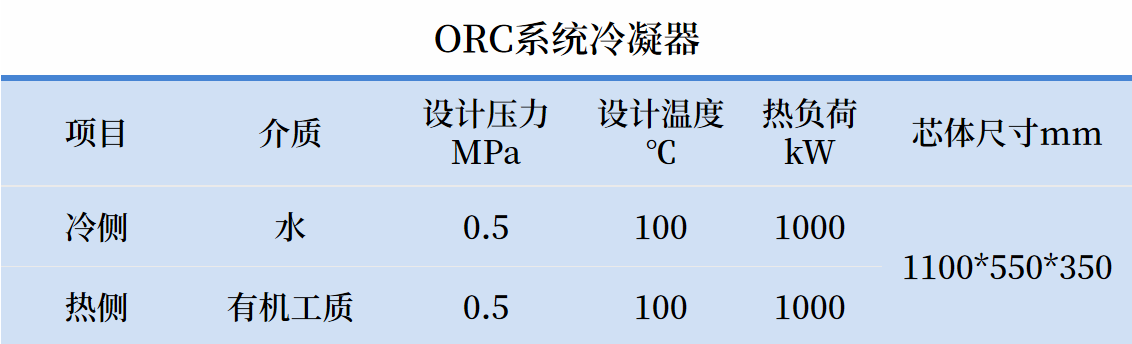

The heat exchanger is in direct contact with the heat source and the cold source, and is one of the key devices of the entire organic Rankine cycle. Its heat exchange efficiency has an important impact on the efficiency of the organic Rankine cycle. The design of the heat exchanger needs to be carried out according to the type and characteristics of the waste heat, including evaporators, condensers, preheaters, etc., and it is also necessary to consider issues such as anti-corrosion, anti-wear, dust and scale removal, and resistance reduction.

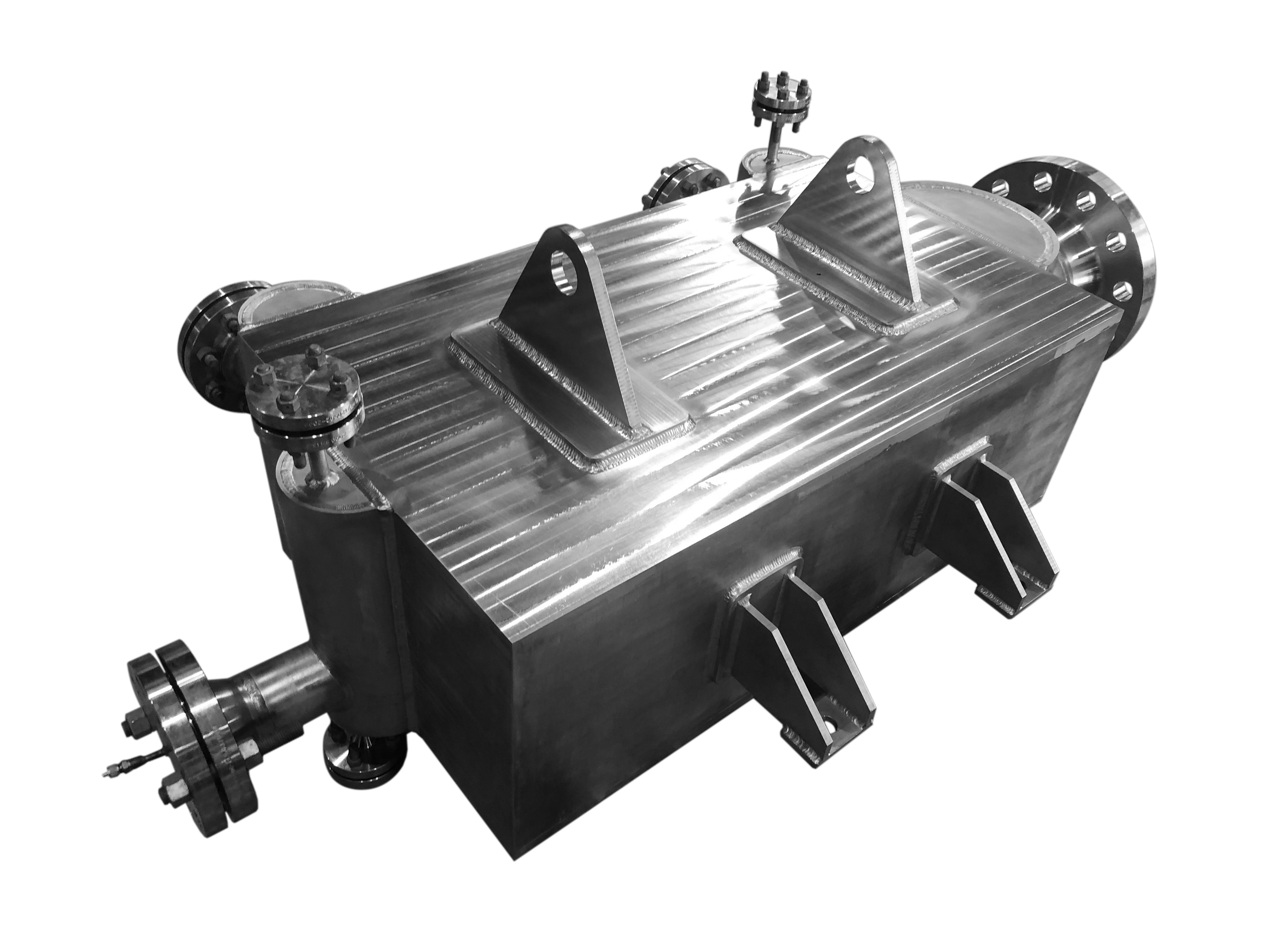

Diffusion welded plate-fin heat exchanger (PFHE) is suitable for heat exchange between gas and liquid and gas and gas. Compared with brazed plate-fin heat exchanger, it has the advantages of no solder, strong corrosion resistance (chlorine, acid, alkali, ammonia, mercury, etc.), high and low temperature resistance (-200~900℃), high pressure resistance (4-15MPa), low leakage rate (1*10-9Pa·m3/s), wide range of material application (titanium, stainless steel, nickel white copper, etc.). At the same time, secondary welding has no effect on the diffusion welding core weld.

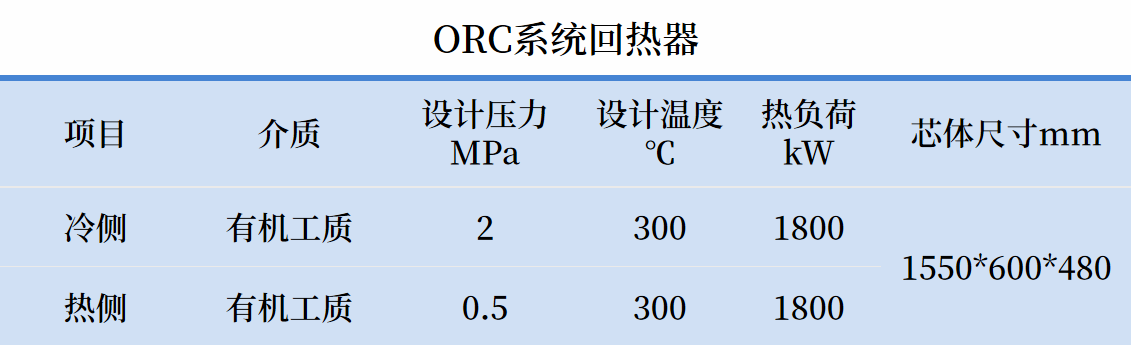

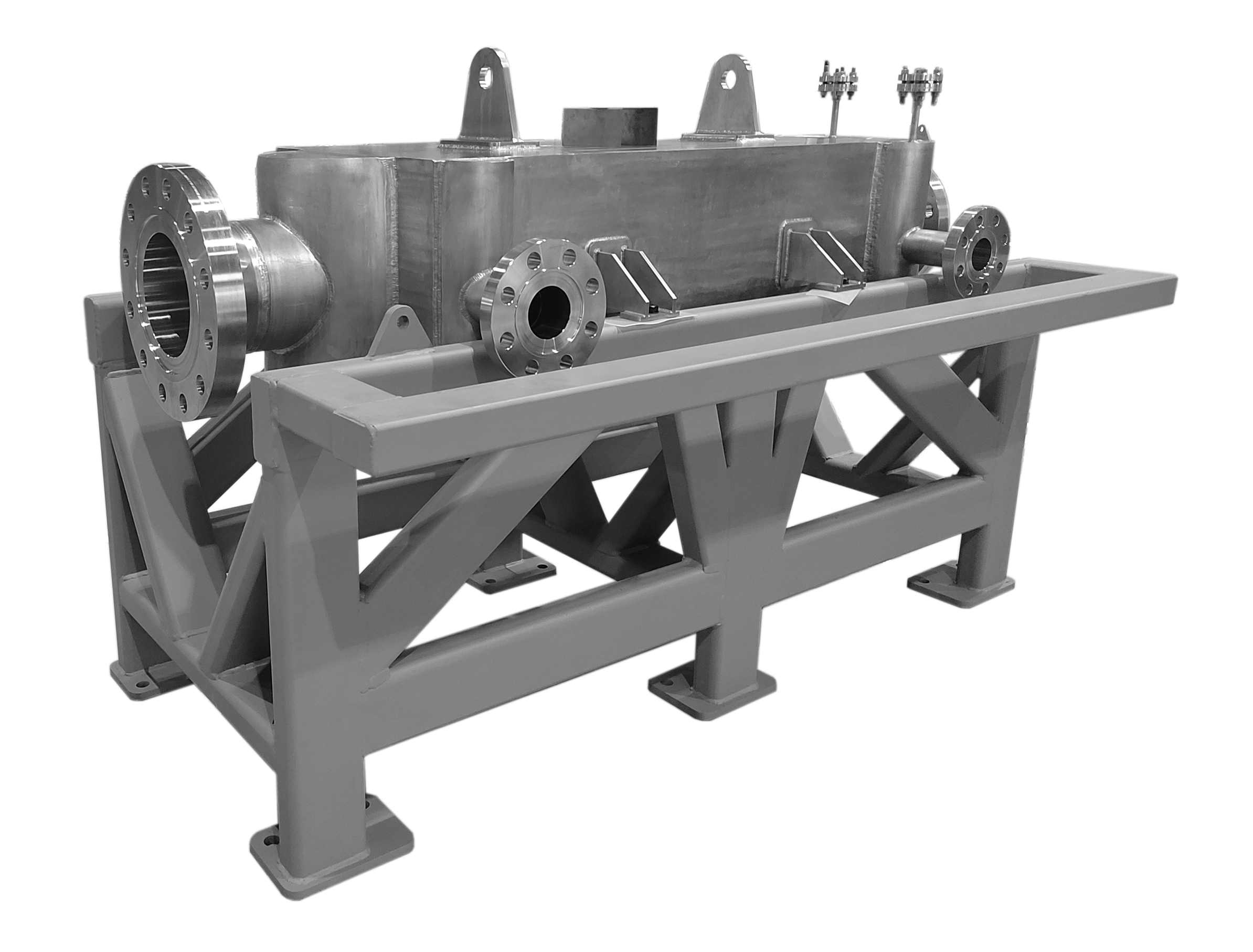

The PFHE developed and produced by Shenshi Energy Saving is suitable for the organic Rankine cycle system. It has the characteristics of small size, high power, and solder-free welding. It has safety, high performance and high reliability.