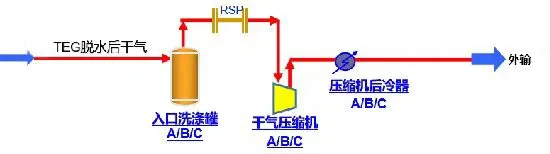

During the cooling process, the high-temperature dry gas treated by the dry gas compressor is filtered by the filter placed before the inlet of the hot side of the compressor aftercooler, and then enters the heat exchanger. It exchanges heat with the circulating cooling water distributed by the cooling water pump and filtered by the backwash filter placed before the inlet of the cold side of the cooler. The dry gas is cooled to about 40~45℃ in the aftercooler, creating ideal conditions for offshore pipeline transportation.

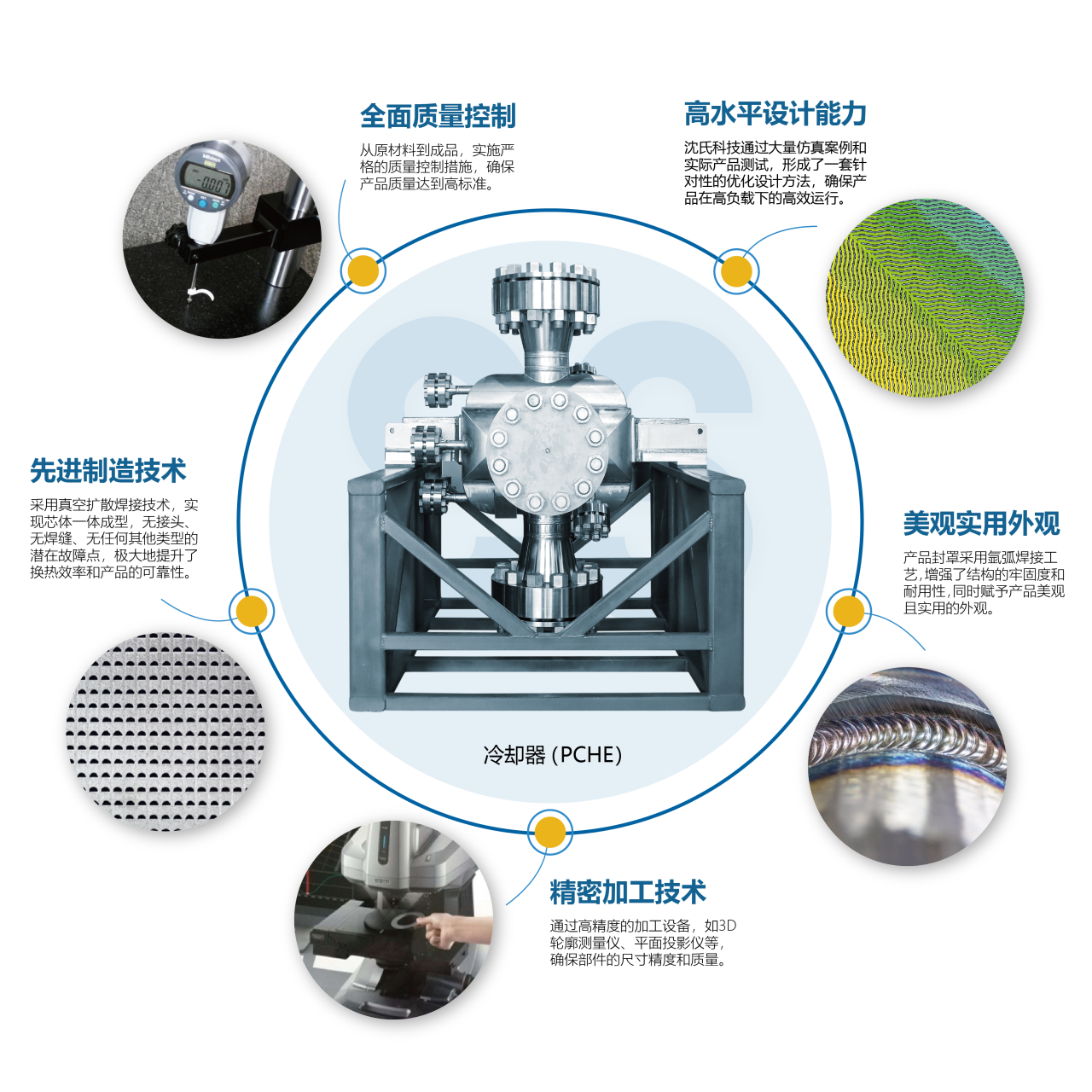

The dry gas compressor aftercooler of this project of Shenshi Technology can withstand the design pressure of 27900kPaG and withstand high and low temperatures of 175℃~-19℃, which greatly improves the safety of offshore oil and gas platforms and ensures production efficiency. The excellent The performance of this product is due to the unique printed plate heat exchanger (PCHE) structure, which can not only greatly improve the heat exchange efficiency, but also withstand extreme temperatures and pressures. Under the same working conditions, compared with the traditional shell and tube heat exchanger, the footprint and weight of Shenshi Technology PCHE are only 15% to 20% of it, which greatly reduces the platform's footprint and weight load, and provides more space and weight margin for other equipment and operations. HZSS Technology PCHE has fewer external welds and less welding, which greatly reduces the possibility of leakage and enhances the overall operational reliability. The product is 2.3 meters long, 2.2 meters wide and 2.1 meters high. During the manufacturing process, HZSS Technology overcame many challenges. From design optimization, material selection to welding technology and quality control, every link reflects the professional strength of HZSS Technology.

The delivery of the dry gas compressor aftercooler is the continued technological innovation and pursuit of excellence of HZSS Technology. It is also a vivid practice of the concept of "integrated wisdom innovation, ecological technology", and it has fulfilled HZSS Technology's commitment to promoting the high-quality development of the offshore shipbuilding industry. In the future, HZSS Technology will continue to be committed to every technological breakthrough and contribute more to the realization of a green and low-carbon future.