What is the difference between Shenshi's new shell and tube heat exchanger and others on the market?

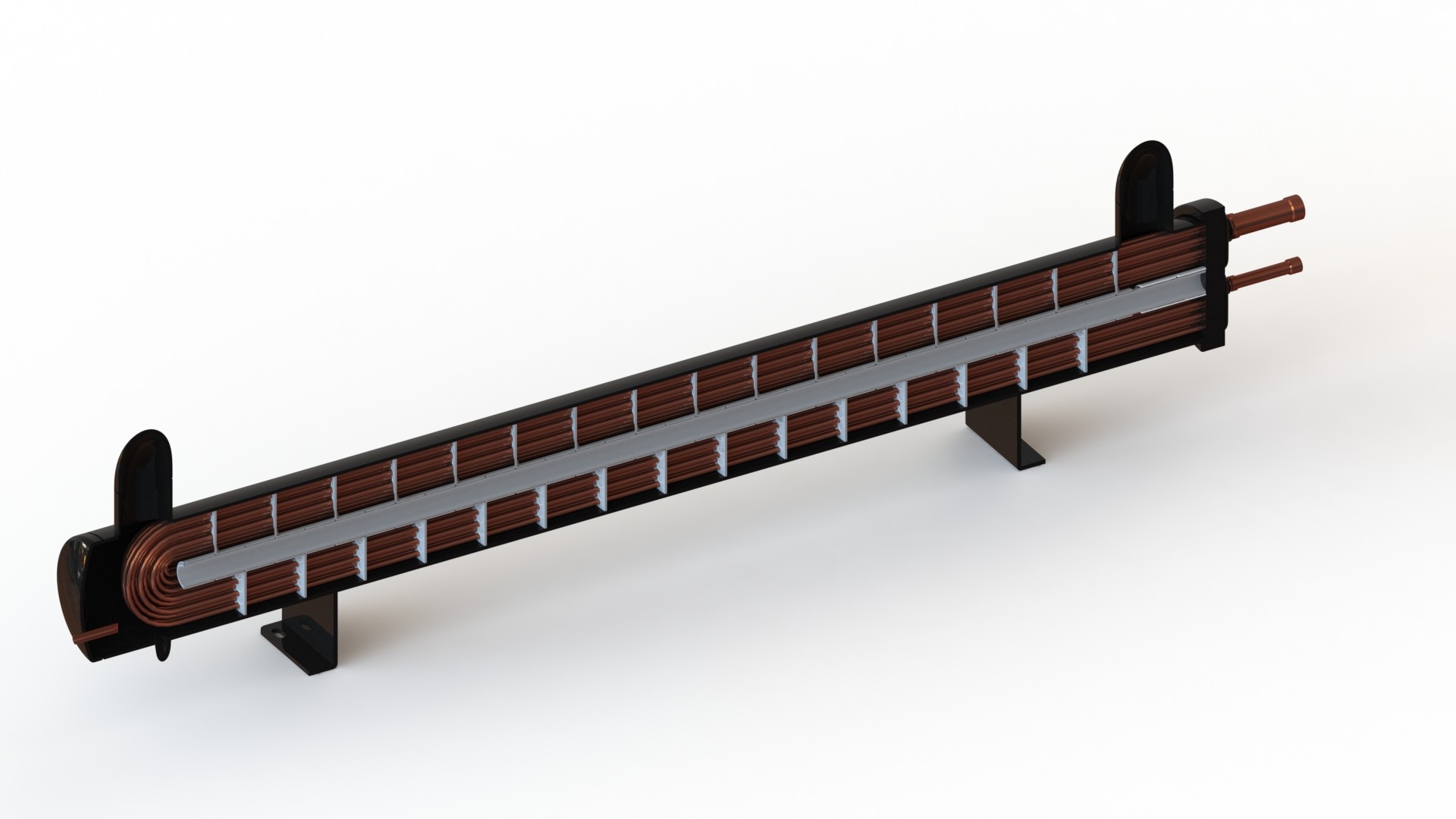

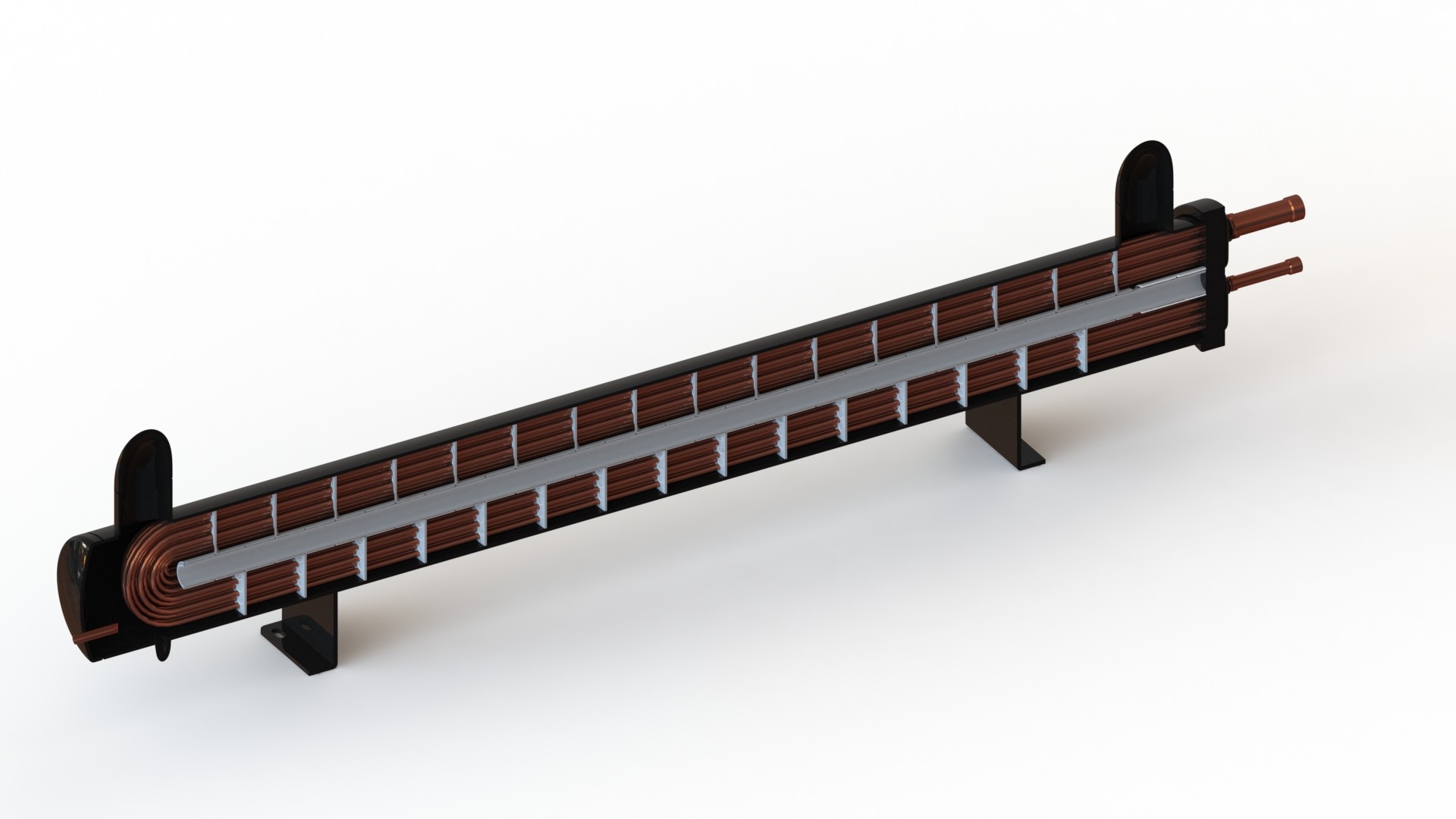

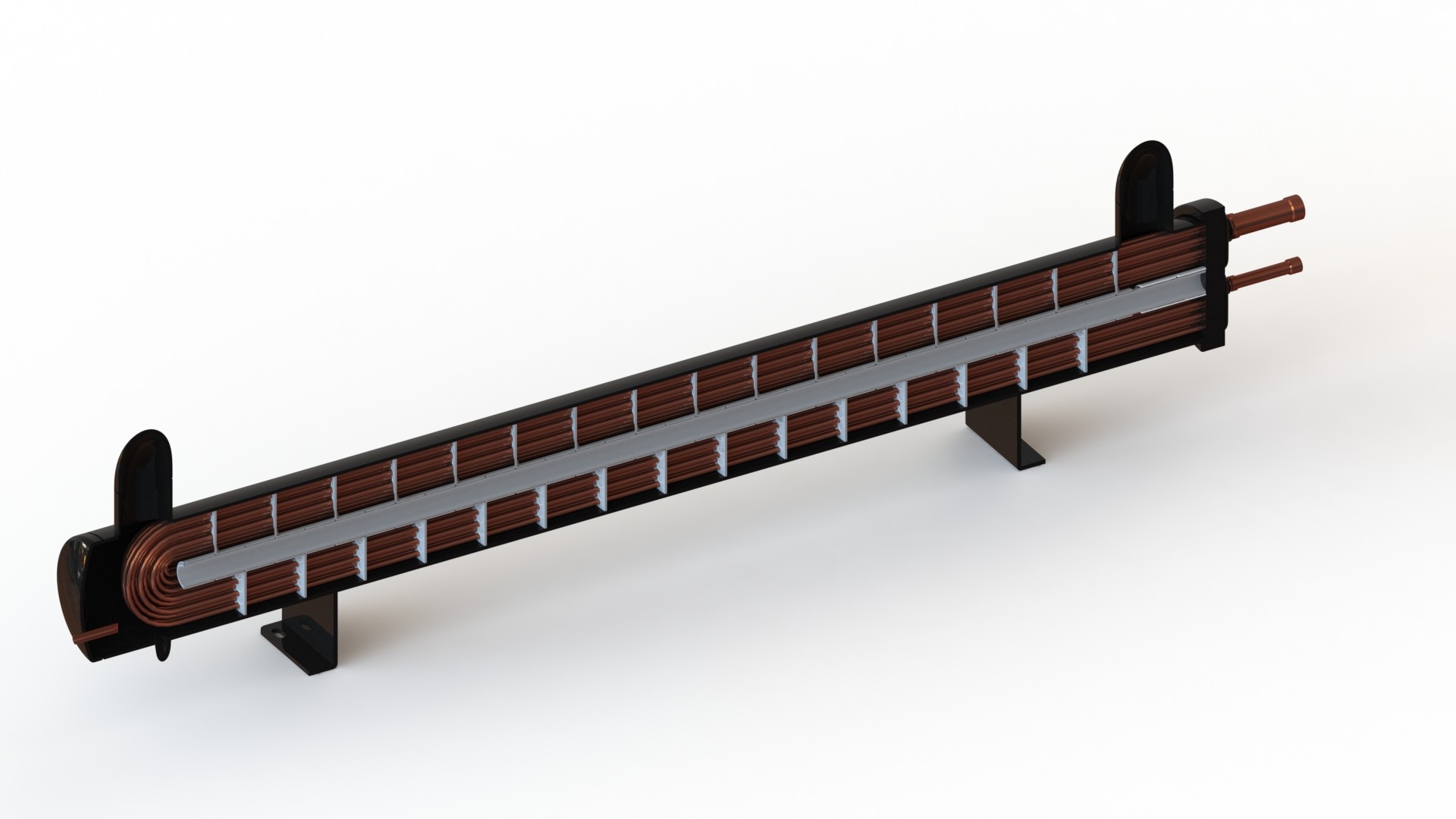

Shenshi's latest 130KW shell and tube heat exchanger embodies a revolutionary leap in thermal technology, meticulously engineered to deliver unmatched performance, reliability, and value. This next-generation system integrates three core advancements that set a new benchmark for the industry.

First, its high-efficiency core is powered by an upgrade to a proprietary 7mm micro-channel heat transfer tube. This precision-engineered tube, with its ultra-thin 0.35mm wall, creates intense internal turbulence, dramatically boosting the heat transfer coefficient. This is synergistically combined with an optimized spiral baffle design that eliminates flow dead zones, ensuring uniform shell-side velocity for maximum thermal exchange. The system is crowned with Shenshi's patented multi-distributor technology, which ensures perfect refrigerant distribution across every tube. This combination guarantees exceptionally high heat exchange efficiency, significantly reducing energy consumption in both refrigeration and heat pump applications.

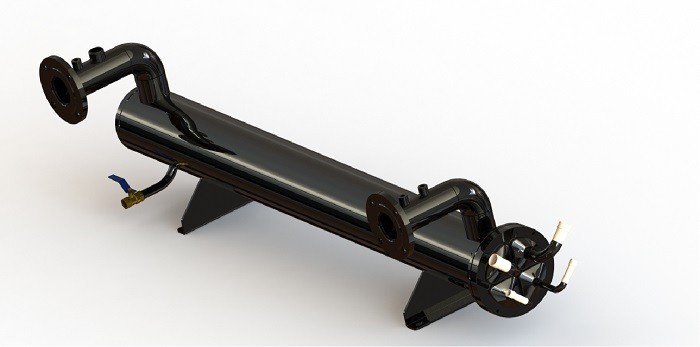

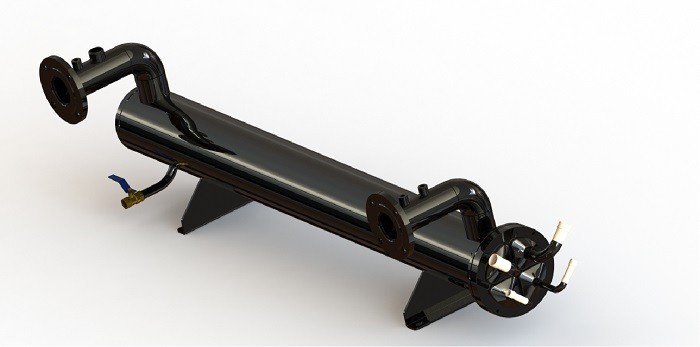

Second, it is built for absolute reliability and safety. Every unit is designed and manufactured in strict accordance with the rigorous GB150 and GB151 pressure vessel standards, ensuring structural integrity under high pressure. The fluorine-side header utilizes advanced laser welding technology instead of traditional gaskets. This creates a seamless, monolithic joint that completely eliminates the risk of leakage—a common failure point in conventional designs. Furthermore, the heat exchange tube is a single, integrally formed piece with no internal splices or solder joints exposed to water. This monolithic construction, combined with the elasticity of the Ω-shaped tube design, provides extraordinary anti-freezing performance, allowing the tube to expand and contract without rupture.

Finally, the design achieves superior compactness and cost-effectiveness. The fluorine-side header features a patented optimized design that reduces material usage without compromising strength or performance. By utilizing smaller diameter tubes within a compact shell, the unit achieves a remarkably high heat transfer area density. This means it delivers the same powerful thermal duty as a much larger traditional exchanger, saving crucial space and material costs. This makes it an ideal, smart-choice solution for modern applications where efficiency, size, and total cost of ownership are paramount.

In summary, Shenshi's 130KW shell and tube heat exchanger is more than just a component; it is a reliable, efficient, and intelligent thermal system built to perform flawlessly in the most demanding environments.