What main processing techniques are used in Shenshi's shell and tube processing?

Laser cutting process

Inner tube bending process

Robot Expander

Laser welding of fluorine side head

Four-axis machining center

Laser welding of fluorine side head

Shenshi's commitment to manufacturing excellence is embodied in our state-of-the-art shell and tube heat exchanger processing techniques. Each method is meticulously selected to ensure unparalleled precision, durability, and performance in every unit we produce.

Our process begins with Laser Cutting Technology, which delivers exceptionally clean and precise cuts on tubes and shell components. This computer-controlled method guarantees perfect dimensional accuracy for every part, forming the critical foundation for a leak-proof and high-integrity assembly.

Next, the Inner Tube Bending Process is executed with high precision to achieve smooth, consistent bends without compromising the internal flow area or creating weak points. This ensures optimal fluid dynamics and heat transfer efficiency within the exchanger, crucial for maintaining system performance.

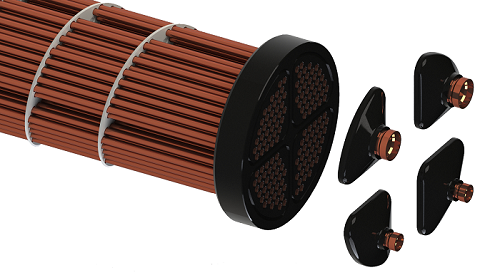

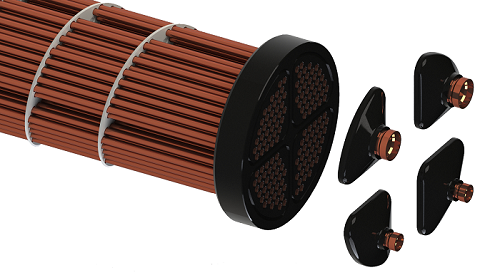

We then utilize Robotic Expander systems to mechanically expand the tubes into the tube sheets. This automated process applies uniform force to create a perfect, tight seal between each tube and the tube sheet, drastically enhancing the structural integrity and preventing leaks under high pressure and thermal cycling.

A cornerstone of our technique is the Laser Welding of the Fluorine Side Head. This advanced welding method provides a deep, narrow, and extremely strong weld seam with minimal thermal distortion. It is particularly vital for creating robust joints in corrosive environments, ensuring long-term reliability when handling aggressive refrigerants.

Finally, our Four-Axis Machining Centers deliver ultimate precision in machining complex components like tube sheets and flanges. This computer numerical control (CNC) technology guarantees that every part is manufactured to exact specifications, ensuring perfect alignment and fit during the final assembly.

By integrating these advanced processing techniques, Shenshi doesn't just build heat exchangers; we engineer reliable, high-performance thermal solutions built to last in the most demanding applications, from industrial refrigeration to chemical processing.