Performance comparison of diffusion bonded high efficiency compact heat exchangers (PCHE)with others

- Share

- Issue Time

- Apr 15,2020

Performance comparison of diffusion bonded high efficiency compact heat exchangers (PCHE)with others

Shenshi high efficiency compact heat exchangers(PCHE)

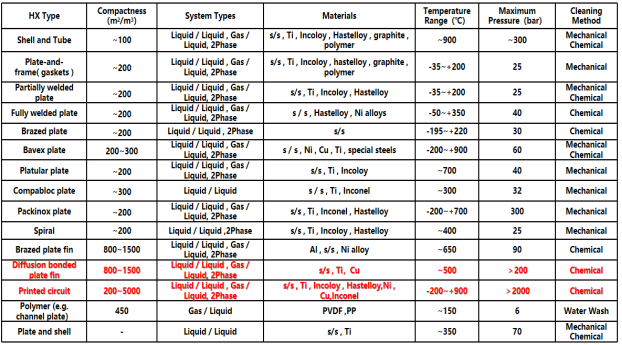

The most striking advantage is its exceptional compactness. PCHEs offer an incredibly high heat transfer surface area density, often achieving the same thermal duty in less than 1/5th the volume of a traditional shell & tube exchanger. This massive space and weight saving is invaluable in offshore platforms, aerospace, and modular plants where footprint is at a premium.

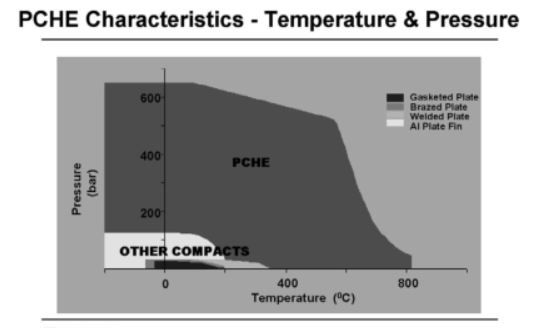

Beyond size, the performance under pressure and temperature is where PCHEs truly dominate. Unlike traditional exchangers that use gaskets or braising, the core of a PCHE is created by diffusion-bonding multiple metal plates into a single, solid block. This monolithic construction allows it to withstand extreme pressures exceeding 600 bar and temperatures from cryogenic to 900°C, far surpassing the limits of plate heat exchangers and welded designs.

Furthermore, PCHEs provide unmatched thermal efficiency. The finely etched, complex flow channels create highly turbulent flow, which drastically improves heat transfer coefficients. This results in significantly closer temperature approaches and higher effectiveness, translating to lower energy consumption and operating costs. For applications like supercritical CO₂ power cycles or LNG liquefaction, this efficiency is not just an advantage—it is a necessity.

While shell & tube exchangers are known for their robustness and plate exchangers for their cost-effectiveness in moderate duties, the PCHE is the definitive solution for the most challenging environments. It seamlessly combines the high-pressure capability of shell & tube with the compact efficiency of plate exchangers, while also introducing unparalleled resilience against thermal fatigue and cross-contamination.

For engineers designing systems for nuclear power, hydrogen production, or deep-sea oil and gas, the performance comparison is clear: for ultimate efficiency, compactness, and reliability under pressure, the diffusion-bonded PCHE is the undisputed leader.