What is integrated microchannel reactor?

- Share

- Issue Time

- Sep 8,2020

What is integrated microchannel reactor?

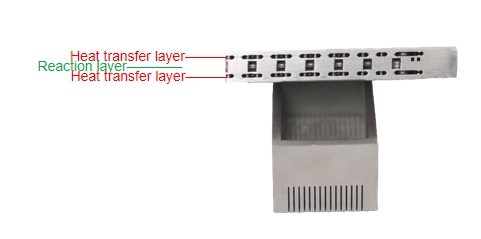

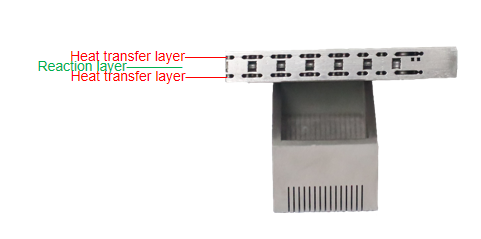

The integrated microchannel reactor is a three-stack structure element that is made of a solid substrate with a small channel size and structure that can be used for chemical reactions by means of precision diffusion bonding technology. The reaction medium flows in the reaction layer channel and completes the required reaction in the channel, and the heat exchange medium is distributed on both sides of the reaction layer to provide the required temperature for the reaction.

Applicable reactions of integrated microchannel reactor:

l Strong exothermic reaction

l Reactions with unstable reactants or products

l Rapid reaction with strict reactant ratio requirements

l Dangerous chemical reaction

l High temperature and high pressure reaction

l Nanomaterials and reactions requiring uniform distribution of products

Integrated Microchannel Reactors: Precision Engineering for Advanced Chemical Processing

An integrated microchannel reactor represents a paradigm shift in chemical reaction technology, leveraging microscale engineering to achieve unprecedented control over reaction parameters. This sophisticated device employs a monolithic three-stack architecture constructed from specialized alloys or advanced ceramics. Through precision diffusion bonding – a solid-state joining process conducted under high temperature and pressure in vacuum conditions – multiple substrate layers are fused into a leak-proof unitary structure without filler materials.

Core Structural Innovation:

Reaction Layer: Central stack featuring intricate channel networks (typically 100μm-2mm) where chemical transformations occur. The high surface-area-to-volume ratio enables near-instantaneous mass/heat transfer.

Thermal Management Layers: Dual heat exchange strata flanking the reaction zone, circulating heating/cooling media with ±0.5°C temperature control precision.

Fluid Distribution Manifolds: Engineered flow fields ensuring uniform reactant distribution across thousands of parallel microchannels.

Operational Superiority:

Enhanced Reaction Kinetics: Laminar flow regimes eliminate mixing inefficiencies, reducing reaction times from hours to minutes.

Intrinsic Safety: Microliter-scale reaction volumes mitigate explosion risks for exothermic processes.

Unmatched Thermal Control: Counter-current heat exchange achieves 10,000 W/m²K heat transfer coefficients – 10× conventional reactors.

Scalability via Numbering-Up: Production capacity increased through parallel reactor units rather than size magnification.

Manufacturing Breakthroughs:

Photochemical etching creates complex channel geometries beyond machining capabilities

Diffusion bonding preserves material corrosion resistance at grain boundaries

Modular design enables catalyst integration (e.g., wall-coated heterogeneous catalysts)

Transformative Applications:

→ Pharmaceutical intermediate synthesis with improved selectivity

→ Continuous-flow nitration/hydrogenation replacing batch reactors

→ Solar fuel generation through photocatalytic water splitting

→ Distributed chemical manufacturing for on-demand production

This technology represents the convergence of precision manufacturing, advanced materials science, and process intensification principles, positioning integrated microreactors as foundational enablers for Industry 4.0 chemical plants. Their capacity to execute reactions under precisely controlled spatial and thermal conditions unlocks pathways to novel chemistries previously deemed commercially unviable.