Working condition of Heat exchanger for hydrogen fuel cell vehicle-mounted hydrogen supply system

- Share

- Issue Time

- Jan 21,2021

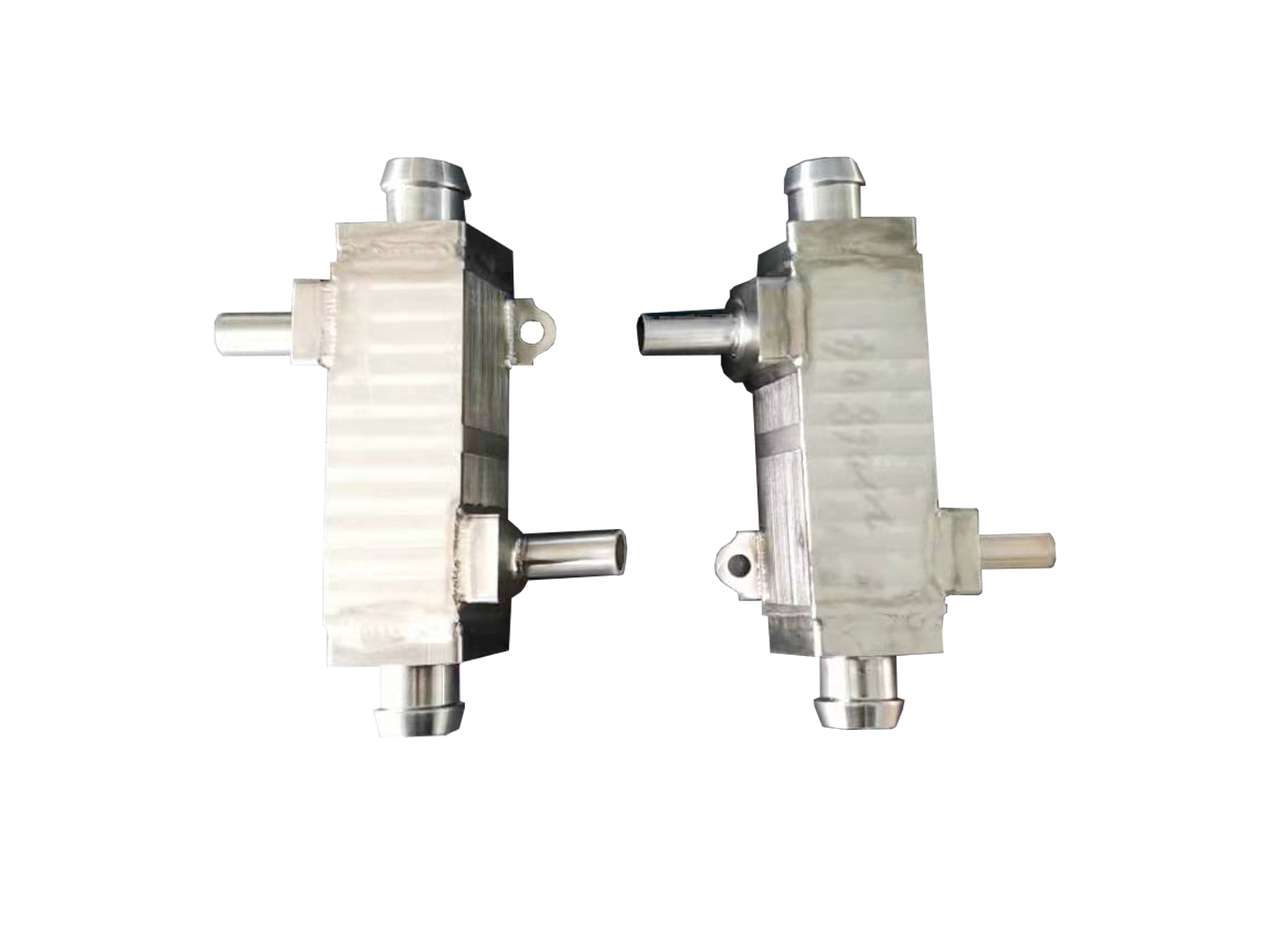

Working Conditions and Features of the Heat Exchanger in Vehicle-Mounted Hydrogen Supply Systems for Fuel Cell Vehicles

The heat exchanger in a vehicle-mounted hydrogen supply system for fuel cell vehicles plays a critical role in maintaining optimal operating conditions. It utilizes a mixture of ethylene glycol and water as the heat transfer medium to regulate the temperature of hydrogen gas released from high-pressure storage bottles. During decompression, the hydrogen undergoes adiabatic expansion, which can cause its temperature to drop significantly. Affected by environmental conditions, the hydrogen’s temperature may reach as low as -40°C. The heat exchanger ensures that the hydrogen is warmed to a suitable temperature for efficient fuel cell operation, even under such extreme conditions.

Microchannel heat exchangers are widely used in these systems due to their distinct advantages, which include:

1. Compact Size and Lightweight Design: Microchannel heat exchangers feature a compact structure, occupying minimal space and reducing weight. This aligns with the stringent requirements for lightweight and space-efficient components in vehicle-mounted systems, enhancing overall vehicle energy efficiency.

2. Safety and Reliability: Designed to withstand high-pressure and low-temperature conditions, microchannel heat exchangers ensure stable and safe operation over extended periods, minimizing the risk of system failures.

3. Resistance to Hydrogen Corrosion and Embrittlement: Hydrogen gas is highly corrosive and can cause hydrogen embrittlement in metals, leading to material degradation. Microchannel heat exchangers are typically constructed with corrosion-resistant materials, such as specialized alloys or coatings, to effectively resist chemical erosion and physical damage, thereby extending service life.

4. High Heat Transfer Efficiency: The microchannel design significantly increases the heat transfer surface area, enabling rapid and efficient temperature regulation of the hydrogen gas. This ensures optimal performance of the fuel cell system.

Additionally, the heat exchanger must adapt to dynamic operating conditions, including vibrations, temperature fluctuations, and varying climatic environments encountered during vehicle operation. Therefore, the choice of materials, structural design, and manufacturing precision are critical to ensuring reliability under such challenging conditions.

In summary, the microchannel heat exchanger in vehicle-mounted hydrogen supply systems is essential for efficient thermal management, ensuring stable hydrogen supply under extreme conditions. Its compact size, lightweight design, safety, reliability, and resistance to hydrogen corrosion and embrittlement make it a vital component in advancing the commercialization of hydrogen fuel cell vehicles.